To adapt a phrase from the 1967 film, The Graduate, “There’s a great future in data centers.” That’s because the explosion of streaming media, artificial intelligence, the internet of things (IoT), cloud services, and all the other elements of this ongoing digital revolution, has created a global construction boom in the data center market. In fact, some research projects the US data center construction market size to grow from $7.24 billion in 2020 to $14.17 billion by 2026.

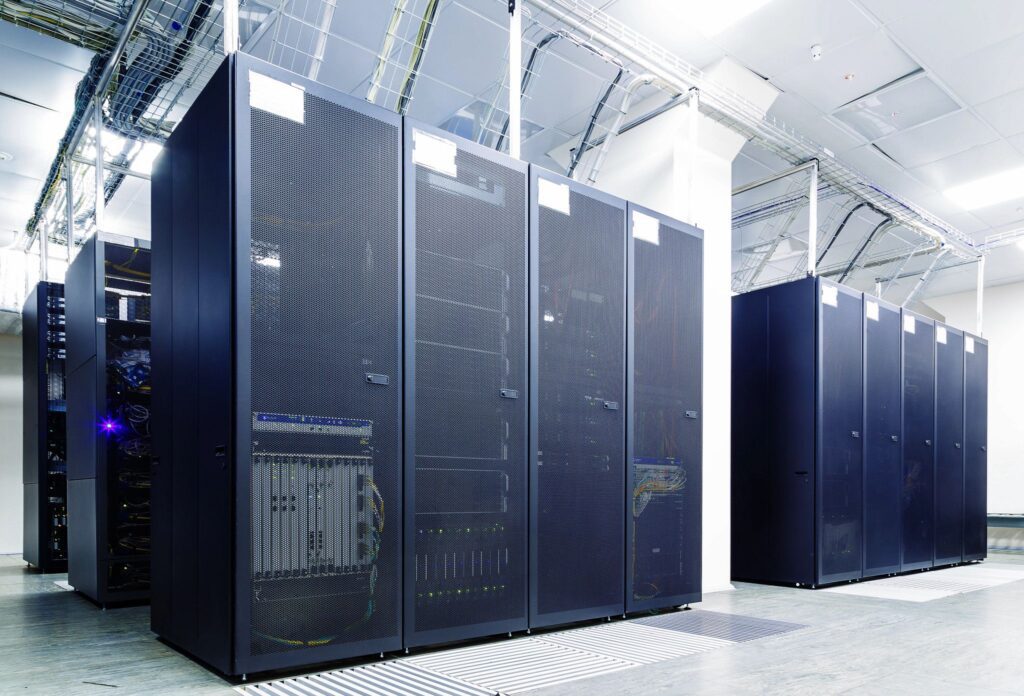

Pre-Engineered Metal Buildings (PEMB) are ideally suited for the requirements of data center structures. As the global PEMB leader, Butler Manufacturing™ has been in the forefront of this surge. Butler Builders and our products have been selected by many of the household names in the commercial cloud infrastructure space, as well as a growing list of corporations that are building out their own digital landscape. As a result, more than 2 million square feet of the most advanced hyperscale data center ecosystems in the world today are Butler® buildings.

Through these projects – not to mention more than a century of experience and innovation prior – we have established a centralized program management for the construction of data centers. This ensures greater continuity, consistency, and design standardization. It also streamlines the construction process for our builders, which ultimately maximizes cost effectiveness over a one-off approach.

This “repeatability” of our data center construction program is crucial to meeting the pace of growth these companies require. We know it works because it has been central to our planning when we facilitated multi-site programs on a regional and national basis.

Keep It Simple...

There are many situations in business (and in life) that benefit from the KISS method. The complexity and frenetic pace of data center construction is a prime example. There are so many variables and moving parts. So, the collaborative controls and single-source responsibility of the design-build construction process make it ideal for the construction of data centers. It provides the guide rails these projects need for success.

Butler Builders have used design-build construction for decades, so applying it to the construction of data centers is a logical approach. The benefits are largely the same as with other construction projects. When the manufacturing process is design-driven, it provides maximum flexibility, transparency of costs, and allows for value-engineering enhancements all while simplifying the supply chain.

While we have found ways to simplify and repeat data center construction, it is important to understand that these are not cookie-cutter solutions. Each client comes with a unique set of requirements that we assess and enhance when possible. That’s why we approach each project with an open mind and a range of options including pre-engineered building systems or conventionally designed structures. Sometimes, the best answer is a hybrid solution using both methods.

Process Meets Products

To this point, we have talked about the various processes that Butler has used to successfully deliver data center construction projects. But all the processes in the world won’t create a durable, energy efficient structure. That’s where our legendary products come in.

Data Centers have unique climate control requirements. It is much easier to manage those requirements in a building that is optimized for thermal performance in the specific geographic location where you are building. Butler owns the industry’s only Guarded Hot Box that we use to test actual 8’ x 10’ roof or wall sections, assembled to the specifications of the project. This provides extremely accurate estimates of the building’s heating and cooling energy consumption and allows us to specify the correct size HVAC units for maximum energy efficiency.

The result of the Guarded Hot Box process is documented, tested assemblies that provide better value for data center construction.

With this as a starting point, you can have confidence in the long-term performance of your roof and wall systems. The MR-24 roof system is widely recognized as the best performing commercial roofing system available. When you combine that with one of our engineered wall systems, it results in substantial life cycle cost savings through gains in energy efficiency.

A Great Future

Butler Manufacturing and our builders have designed and constructed for multiple clients for both co-location and dedicated digital infrastructure. So, whether your data center is for content delivery, cloud service, ecommerce, or general infrastructure, Butler’s unique approach can reduce stress with faster delivery and better budget management.